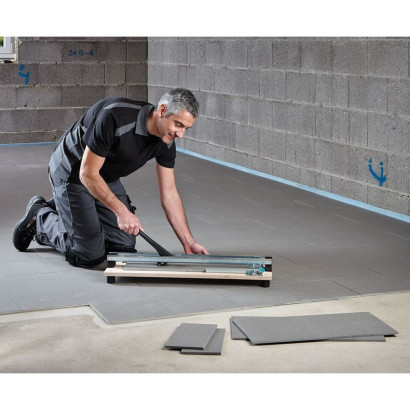

This wolfcraft TC 610 W tile cutter is a reliable tool for cutting and breaking tiles up to a cutting length of 610 mm. It lets you tackle all your challenging tiling projects with confidence.

- Easy to cut tiles: This tile cutting tool is your reliable tool for cutting and breaking tiles up to a cutting length of 610 mm and with a thickness of 3-10 mm.

- Solid professional design on wooden base plate: With its sturdy multiplex base plate, it is a reliable and durable companion for all tiling projects.

- Smooth work: The C-profile rail and triple ball bearing system ensure smooth and continuous work. The integrated metal cone provides a clean tile break.

- Comfortable to work: The breaking wedge is positioned outside the work area so you can position the tile on the base plate without any obstructions.

- Convenient guide rail with stop: An additional guide with angle stop allows you to make precise repeat diagonal cuts.

- Colour: Grey and black

- Material: Metal and plastic

- Dimensions: 79.5 x 25 x 12 cm (L x W x H)

- Tile cutter with solid professional design on wooden base plate

- Cutting length: Max. 610 mm

- Tile thickness: 3-10 mm

- Cutting width with stop: 50-300 mm

- C-profile guide with triple ball bearings

- 15 mm cutting wheel

- Integrated metal cone

- Guide rail with stop for repeat angle cuts

- Stable and robust

- Easy to assemble

- Weight: 5.5 kg

- Delivery contains:

- 1 x Cutting wheel made of tungsten carbide (TCT) with 15 mm diam., bore 6.1 mm

- 1 x Guide rail with angle stop

- 1 x TC 610 W tile cutter

GENERAL SAFETY INSTRUCTIONS • Keep your workplace clean and well lit. Poor housekeeping or unlit working areas may result in accidents. • Do not work with power tools in an explosive ambience, where flammable liquids are kept and where gas or dust occur. Power tools will generate sparks which might ignite the dust or vapours. • Keep children and other persons off your workplace, while using power tools. When getting distracted you can lose the control over the equipment. • The plug of the power tool must fit into the socket. The plug must not be tampered with. Do not use adapters together with grounded power tools. Unmodified plugs and matching sockets will reduce the risk of getting an electric shock. • Keep power tools out of the rain and away from wetness. Water penetrating into a power tool will heighten the risk of getting an electric shock. • When working with a power tool outside, use only extension cords that are suitable for outdoor use. Using an extension cord that is suitable for outdoor use will reduce the risk of getting an electric shock. • If it is unavoidable to use a power tool in a wet ambience, use a residual-current circuit-breaker. It will reduce the risk of getting an electric shock. • Take care of what you do and handle the power tool with care. Never use a power tool, when you feel tired or when you are under the influence of drugs of any kind or alcohol. One moment of inat-tentiveness while using the power tool can cause severe injuries. • Do wear suitable personal protective clothing and equipment, such as hearing protection, goggles, dust masks while doing dust-generating jobs as well as protective gloves, when processing rough materials and when changing tools. • Remove the setting tools or wrenches before switching on the power tool. A tool or wrench at-tached to a rotating part of the equipment may cause injuries. • Wear suitable clothes, i.e. no loose garments or jewellery. Keep your hair, clothing and gloves away from rotating parts. Loose garments, jewellery or long hair may be caught by such rotating parts. • Always use the protective hood with the dust extractor. • Do not use power tools with a defective switch. A power tool that can no longer be switched on or off is dangerous and needs repairing. • Keep unused power tools out of the reach of children. Do not allow persons using equipment which they are not familiar with it, or persons who have not read these instructions. Power tools pose a danger, when being used by inexperienced persons. • Check before starting to work, whether equipment and tools function properly. Never work with damaged or blunt tools. • Have your power tools only repaired by duly qualified personnel. Demand original spares, so that the safety of the power tool remains ensured. • Pull the plug from the socket and/or remove the battery pack from the power tools before you change the setting of your equipment or before you replace any components. The unin-tentional re-start of a power tool may cause accidents. • Put up the machine table properly before installing the power tool. The table’s safe assem-bly is vital to prevent it from collapsing. • Attach the power tool safely to the machine plate before using it. If the power tool gets out of place on the machine plate, you may lose control of it. • Put the machine table on a firm, plain and horizontal surface. If the machine table can shift or wobble, neither the power tool nor the work piece can be moved safely and steadily. • Do not overload the machine table and do not use it as ladder or scaffolding. Excess loads or standing on the machine table can shift the table’s centre of gravity upwards, so that it may topple over. • Do not process any other materials than wood or easily machinable plastic. Exception: It is also allowed processing easily machinable metals (e.g. aluminium), but only with the jig-saw and a suitable saw blade • Loose splinters, chips or similar residues must not be removed by hand from the area close to the running saw blade! • The machines used must conform to DIN EN 60745-1. Equipment built after 1994 must bear the CE sign. • Do not merely saw by hand without a guiding aid; use the parallel or the angle guide. • Saw blades must not be slowed down by pushing from the side after the drive has been deactivated! • Use the tools for their intended purpose only. • Use only faultless saw blades; the base body must not be thicker and the width of the set of teeth not narrower than the thickness of the splitting wedge. • Make regular checks, whether all screws are tightened firmly! • Never use your workbench in an improper way or for purposes other than intended! • Remove all objects from the workbench that are not required. • Do not use the machine for cutting firewood. • Do not use the machine table for cutting log wood. • The power tools must only be switched on and off via the safety switch. • Use only the switch clamp supplied to permanently fix the appliance switch in the „ON“ position. • Always use a push stick when processing small or narrow work pieces. • When not in use, hang the push stick on the bracket provided (Fig. 8). • Make sure that the two swivelling brackets for securing the table legs are seated correctly with the safety bolts inserted in the holes in the side section and that the knurled screws are firmly tightened (Fig. 15.3). • Before starting work, make sure that the hand-held circular saw, router or jigsaw is properly attached to the machine plate, the machine plate is safely arrested in the notch on the machine table and the Allen wrench is inserted for additional safety (Fig. 17.3). • Do not use the machine outdoors in the rain. • Observe the maximum permitted workpiece dimensions (see Technical data).